Air intake technology in vehicles has progressed significantly over centuries, from basic holes to complex systems. Early advancements like carburetors improved performance, while later developments focused on efficiency and emissions reduction. Modern air intake installation kits use advanced materials and designs to enhance fuel efficiency, power output, and engine control, marking a significant leap from primitive automotive breathing mechanisms. These kits integrate seamlessly with suspension parts and exhaust mufflers, featuring optimized airflow patterns, high-flow filters, and temperature control elements for improved performance and reduced emissions.

“Unleash the power within your vehicle with an exploration of the modern air intake installation kits. From humble beginnings, air intake technology has evolved dramatically over time. This article delves into the rich historical perspective, highlighting key advancements that shaped today’s advanced systems. We’ll then dissect the features and benefits of modern kits, showcasing their ability to boost performance, enhance cooling, and increase power output. Furthermore, we’ll gaze into the future, revealing emerging trends such as advanced materials, customization options, and the shift towards eco-friendly solutions, all while navigating regulatory changes in air intake design.”

- Historical Perspective of Air Intake Technology

- – Brief overview of early vehicle air intake systems

- – Key advancements that led to modern air intake design

Historical Perspective of Air Intake Technology

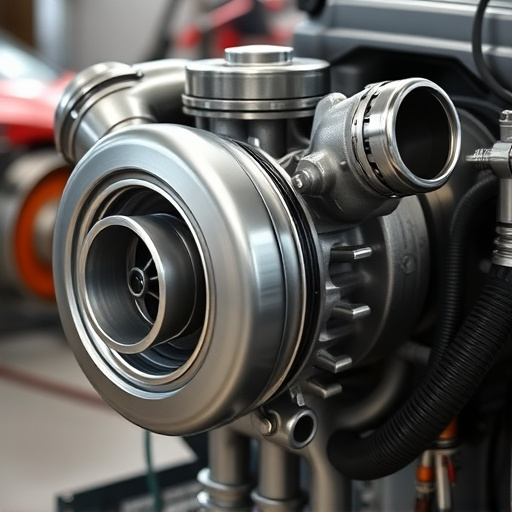

The history of air intake technology dates back to the early days of automotive innovation. In the beginning, vehicles relied on simple and primitive intake systems, often little more than a hole in the engine’s side, allowing air to enter directly. As engines became more complex, so too did their breathing requirements. The introduction of carburetors in the early 20th century marked a significant step forward, enabling more precise control over fuel mixture and enhancing performance.

Over time, advancements in engineering led to the development of more sophisticated air intake systems. The integration of air filters improved engine efficiency by removing contaminants, while cold air intake systems, which direct cool, dense air from outside the vehicle into the engine, have been shown to boost power output. This evolution continues today, with modern air intake installation kits incorporating advanced materials and designs to enhance fuel efficiency, reduce emissions, and provide better control over engine performance—a far cry from the rudimentary beginnings of automotive breathing mechanisms.

– Brief overview of early vehicle air intake systems

Early vehicle air intake systems were relatively simple in design, focusing primarily on drawing in fresh air from the environment to support combustion. These systems often consisted of a basic air filter housed within a metal or plastic casing, mounted directly to the engine. The air would then be directed into the engine’s intake manifold, enabling the efficient burning of fuel and power generation. Over time, as vehicle performance demands grew, so did the complexity of these systems.

This evolution led to the development of more advanced air intake installation kits that integrated seamlessly with a vehicle’s existing components, such as suspension parts and exhaust mufflers. Modern kits often incorporate innovative designs featuring optimized airflow patterns, high-flow filters, and even temperature control elements. These enhancements not only improve engine performance but also contribute to better fuel efficiency and reduced emissions, reflecting the industry’s ongoing commitment to both power and sustainability.

– Key advancements that led to modern air intake design

The evolution of modern air intake design is deeply rooted in advancements made in automotive engineering and materials science. Initially, air intake systems were simple, often consisting of little more than a filter and ducting. However, the push for performance and efficiency in vehicles led to key innovations. One significant advancement was the introduction of high-flow air filters, which improved airflow and, consequently, engine power. These early developments set the stage for more sophisticated designs to come.

Additionally, advancements in materials allowed manufacturers to create lighter, more durable components. Stainless steel and aluminum became prevalent, replacing heavy metal components that could restrict airflow and increase backpressure. This shift not only enhanced performance but also improved fuel efficiency. Furthermore, integrating air intake kits with vehicle’s existing systems, such as suspension and brake components, enabled engineers to optimize the overall performance of the car, ensuring a smoother ride and better control while maintaining robust air intake capabilities.

The evolution of modern air intake installation kits reflects a remarkable journey, transitioning from rudimentary early systems to sophisticated designs. Through key advancements in materials, engineering, and performance requirements, today’s air intake kits not only enhance engine efficiency but also contribute to the overall driving experience. As vehicle technology continues to advance, future innovations in air intake design will undoubtedly further optimize performance, sustainability, and customization for a diverse range of driving needs.